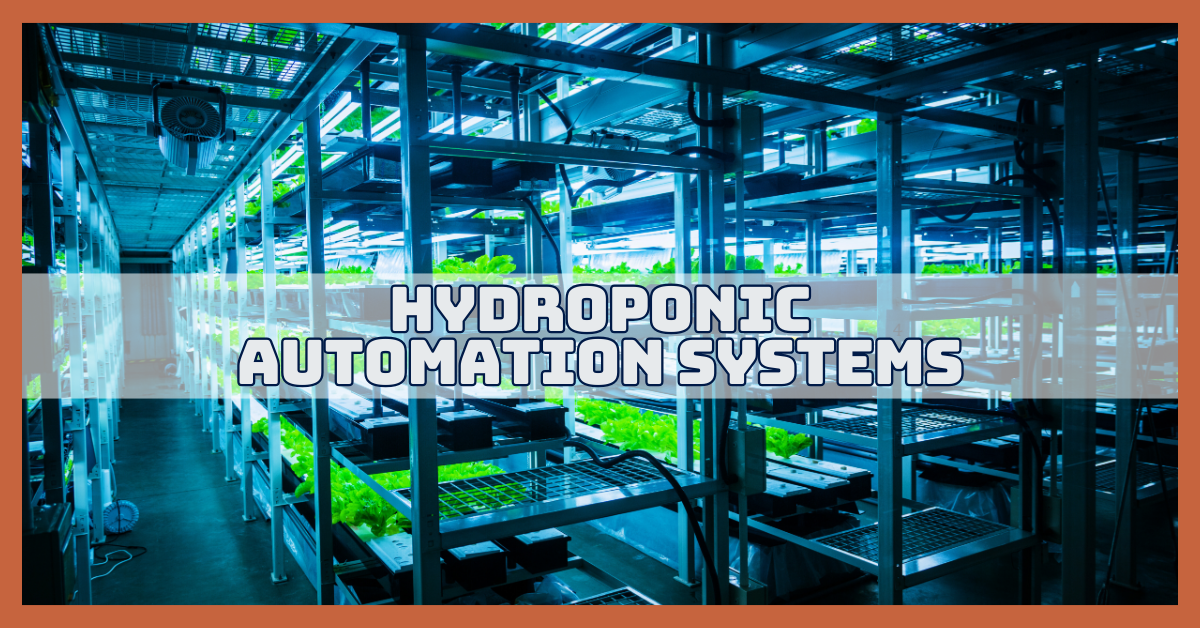

Best Hydroponic Automation Systems For Faster Growth

A Hydroponic Automation System is revolutionizing how we grow plants by combining technology with precision. It automatically manages water, nutrients, and lighting, creating perfect conditions for healthy, faster growth.

This method increases yields, decreases waste, and saves time, making it ideal for both novice and seasoned growers.

With less manual work and more consistent results, it’s paving the way for a brighter, more sustainable future in gardening and farming.

Types Of Hydroponic Automation Systems

Hydroponic automation revolutionizes soilless farming by using technology to optimize nutrient delivery, climate control, and lighting—boosting efficiency, reducing labour, and maximizing crop yields in modern indoor gardens.

1. Nutrient Delivery Automation Systems

Nutrient delivery automation systems are designed to mix and deliver nutrient-rich water to hydroponic plants precisely.

They work by using sensors to continuously measure the nutrient concentration, pH, and water levels in the reservoir. These sensors feed real-time data to a controller, which activates dosing pumps to add nutrients or adjust pH as needed.

To create such a system, you need nutrient tanks, peristaltic dosing pumps, pH and EC (electrical conductivity) sensors, and a central programmable logic controller (PLC) or microcontroller like Arduino.

Setup involves calibrating sensors and programming dosing cycles. Entry-level DIY kits cost around $300, while professional systems with multiple dosing channels and advanced controls can run up to $2,500 or more.

2. Environmental Control Automation Systems

Environmental control automation manages critical growing conditions such as temperature, humidity, CO₂ concentration, and lighting intensity. It works by deploying sensors throughout the grow room that continuously monitor these factors.

Data is sent to an intelligent controller that automatically adjusts heating, cooling, ventilation fans, humidifiers, CO₂ injectors, and LED grow lights to maintain optimal conditions.

Building this system involves integrating environmental sensors (temperature, humidity, CO₂), HVAC devices, and lighting with a central intelligent controller or automation hub.

Many growers use platforms like Raspberry Pi or commercial controllers with mobile app support. Basic environmental controllers start at around $400, while fully integrated climate control systems designed for large-scale operations can exceed $3,000.

3. Irrigation And Watering Automation Systems

Automated irrigation systems optimize watering by delivering precise water amounts at the correct times. These systems employ moisture sensors or timers that monitor root zone moisture levels or irrigation schedules.

When moisture drops below a threshold, the system triggers pumps or solenoid valves to irrigate the plants, preventing over- or under-watering.

To create this, you’ll need moisture sensors, water pumps, tubing, and a timer or programmable controller. Wiring everything together allows the system to respond dynamically to plants’ water needs.

Simple DIY kits are available for as low as $100, while more sophisticated multi-zone irrigation controllers with moisture sensors can cost between $500 and $1,500, depending on capacity and features.

4. Lighting Automation Systems

Lighting automation ensures plants receive the proper light duration and intensity necessary for photosynthesis and growth stages.

It works using programmable timers or smart controllers that turn grow lights on or off and adjust brightness according to a preset schedule or ambient light levels.

Light sensors can also detect natural sunlight and adjust artificial lighting accordingly to save energy. Setting this up requires installing dimmable LED grow lights compatible with your controller system, timers, and optionally, light sensors.

A simple timer setup can be installed for about $50, while advanced innovative lighting systems with app-based control and sensors typically cost between $200 and $800, depending on sophistication and scale.

5. Climate Monitoring And Control Systems

Climate monitoring automation involves a network of sensors that measure temperature, humidity, and CO₂ levels throughout the grow space.

These sensors transmit data to a climate control unit that automatically regulates HVAC systems, fans, heaters, humidifiers, and CO₂ injectors to maintain optimal growing conditions.

The system prevents stress on plants caused by environmental fluctuations. To build this, you install ecological sensors linked to a programmable controller or smart home automation hub. Devices like smart thermostats and humidifiers can be integrated for automatic adjustments.

Entry-level climate monitoring kits can be purchased for around $150, but comprehensive climate control solutions for commercial hydroponics might exceed $4,000.

6. pH and EC (Electrical Conductivity) Automation Systems

For plants to absorb nutrients, the nutrient solution's pH and electrical conductivity (EC) must be kept at the proper levels. Automated pH and EC systems use probes to monitor these values and send data to a controller continuously.

The controller then activates dosing pumps that add acids, bases, or concentrated nutrients to adjust the solution to ideal levels.

Setting up such a system requires pH and EC sensors, dosing pumps, nutrient reservoirs, and a programmable controller. Proper calibration is essential for accuracy.

Entry-level setups for hobbyists can start at $300, while commercial-grade systems offering precise dosing and data logging range from $1,000 to $3,000 or more.

7. Data Logging And Remote Monitoring Systems

Data logging automation collects continuous data from various sensors monitoring nutrient levels, climate conditions, and system health. This data is stored locally or uploaded to cloud services for real-time monitoring and historical analysis.

Remote monitoring allows growers to track their hydroponic system via smartphone or computer, receiving alerts about any issues such as low nutrients or equipment failure. Setting this up involves installing sensors, a data logger or IoT controller, and ensuring reliable internet connectivity.

Basic DIY monitoring kits can cost around $200, while fully integrated professional IoT platforms with cloud analytics and alerts may cost over $1,000, depending on sensor quantity and service fees.

8. Harvesting And Growth Tracking Automation

Advanced hydroponic systems increasingly incorporate cameras and artificial intelligence (AI) to track plant growth, detect diseases, and optimize harvest timing.

Cameras capture high-resolution images, which AI algorithms analyze to estimate plant size, leaf health, and pest presence.

Without having to perform physical inspection, producers may use this data to make well-informed decisions regarding fertilization, trimming, and harvesting.

Setting this up requires installing IP cameras, image processing software, and a cloud or local AI platform integrated with your hydroponic control system.

While more complex and costly, basic camera monitoring starts around $1,500, with AI-powered precision agriculture systems for commercial farms costing $5,000 or more.

Benefits Of Using Hydroponic Automation Systems

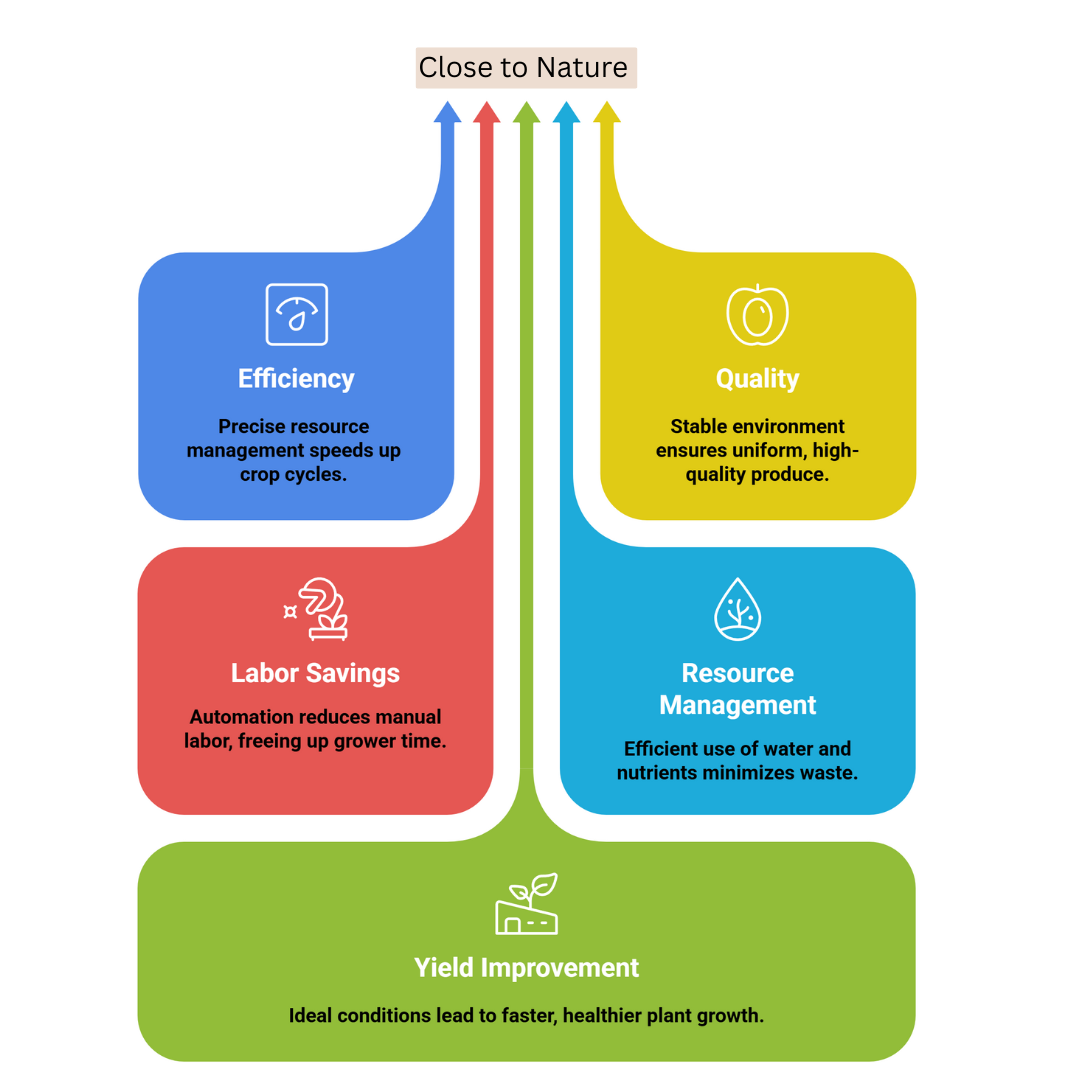

Hydroponic automation systems revolutionize indoor farming by optimizing resource use, improving crop quality, and reducing labour.

These innovative technologies enable efficient, consistent, and scalable plant growth for year-round harvests.

1. Increased Efficiency

Hydroponic automation systems significantly improve growing efficiency by precisely managing nutrient delivery, watering schedules, lighting, and climate controls.

To make sure plants get the precise amount of water and nutrients they require at the proper moment, these systems use sensors and timers.

This precise control reduces waste of resources like water and fertilizers, which are often overused in manual setups. Automation also speeds up routine tasks, enabling faster turnaround times for crop cycles.

Overall, this enhanced efficiency leads to healthier plants, lower input costs, and a more streamlined growing process that maximizes output from limited space.

2. Consistent Crop Quality

Automated hydroponic systems provide a stable environment where temperature, humidity, nutrient concentration, and light intensity are carefully controlled.

This consistency helps avoid the fluctuations that often stress plants and cause uneven growth or produce quality variations. With automation, each plant receives uniform treatment, resulting in crops with consistent size, flavour, and texture.

This uniformity is essential for commercial growers who need reliable product quality to meet customer expectations and market standards. Consistent crop quality improves brand reputation and reduces waste due to rejected or low-quality produce.

3. Labour Savings

One of the major benefits of hydroponic automation is the significant reduction in manual labour requirements. Automated systems handle time-consuming and repetitive tasks such as watering, feeding, pH balancing, and climate regulation without human intervention.

This frees growers from routine chores, allowing them to focus on monitoring, planning, and optimizing growth conditions. For larger hydroponic farms, labour savings can translate into lower operational costs and fewer staff needed.

Automation also reduces human error in daily tasks, improving reliability and freeing up time for innovation and expansion.

4. Better Resource Management

Hydroponic automation allows growers to use water and nutrients more efficiently by continuously monitoring and adjusting inputs based on real-time plant needs.

Sensors track parameters like moisture, pH, and nutrient levels, enabling precise dosing and minimizing waste. This careful management conserves water—a critical advantage in drought-prone areas—and reduces fertilizer runoff that can harm the environment.

Automated systems recycle unused nutrient solutions, further reducing consumption. Efficient resource use lowers operational costs and supports sustainable farming practices, aligning with growing consumer demand for environmentally friendly agriculture.

5. Improved Crop Yields

Higher yields are possible because hydroponic automation continuously maintains optimal growth conditions, allowing plants to grow more quickly and healthily.

Automated control of light cycles, temperature, humidity, and nutrient delivery optimizes photosynthesis and nutrient uptake.

Plants experience less stress and are less vulnerable to diseases caused by environmental fluctuations. By eliminating human errors in feeding and watering, the system supports steady, vigorous growth.

Growers can harvest more produce in shorter cycles compared to traditional soil farming, making hydroponic automation especially attractive for commercial growers seeking to maximize productivity in limited spaces.

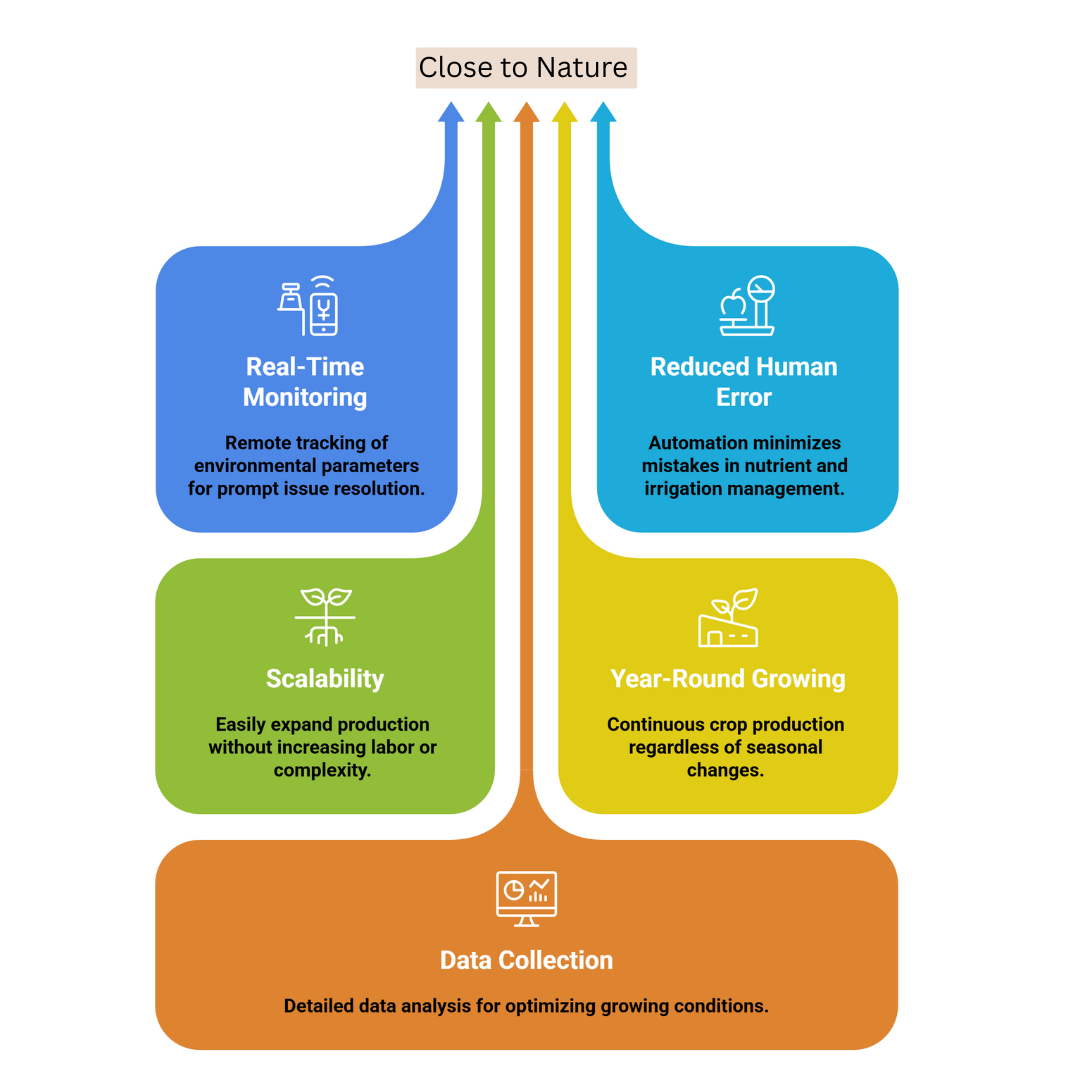

6. Real-Time Monitoring And Control

Modern hydroponic automation systems come with remote monitoring features that allow growers to track environmental parameters such as temperature, humidity, nutrient levels, and lighting from anywhere using smartphones or computers.

This real-time data access helps detect and address issues promptly, preventing crop damage before it becomes severe.

Automated alerts can notify growers of any system malfunctions or out-of-range values. This proactive management reduces downtime and improves crop health.

Remote control capabilities also make it possible to adjust settings instantly, ensuring the growing environment is continually optimized even when the grower is off-site.

7. Reduced Risk Of Human Error

Manual hydroponic growing involves numerous delicate tasks like measuring nutrient concentrations, adjusting pH levels, and scheduling irrigation.

Mistakes in these areas can stress plants or cause deficiencies and toxicity. Automation removes much of this guesswork by using sensors and programmable systems to carry out these tasks accurately and consistently.

By minimizing human involvement in routine processes, the risk of under- or over-watering and nutrient misapplication is significantly reduced.

This leads to healthier plants, more predictable results, and less wasted time and resources trying to fix problems caused by human error.

8. Scalability

Hydroponic automation systems are highly scalable, making it easy to expand production without proportionally increasing labour or complexity.

Whether operating a small home setup or a large commercial farm, automation can be adapted to control multiple growing units or sections efficiently.

As demand grows, growers can integrate additional sensors, pumps, lights, and controllers seamlessly into their existing system.

This modularity means growers can start small with minimal investment and scale up gradually while maintaining precise control.

In addition to helping businesses expand, automated scalability enables farmers to satisfy consumer needs without compromising productivity or quality.

9. Year-Round Growing

Hydroponic automation enables growers to produce crops continuously throughout the year, regardless of outdoor weather or seasonal changes.

By controlling temperature, light duration, humidity, and nutrient supply, automated systems create ideal conditions for plant growth indoors or in greenhouses.

This consistency allows multiple crop cycles annually, increasing total production. Additionally, year-round cultivation lowers the chance of crop loss from severe weather and reliance on seasonal harvests.

Consumers benefit from a steady supply of fresh produce, while growers gain a reliable income stream. Automation ensures optimal conditions are maintained without manual intervention, supporting sustainable production.

10. Data Collection For Optimization

Automated hydroponic systems often include data logging capabilities that collect detailed records of environmental conditions, nutrient usage, and plant growth rates over time.

This data provides valuable insights for growers to analyze trends, identify bottlenecks, and optimize the growing process.

By reviewing historical information, growers can fine-tune nutrient formulas, adjust lighting schedules, and improve irrigation strategies to maximize plant health and yield.

Data-driven decisions reduce trial and error and help achieve consistent, repeatable results. This ongoing development may result in new growing methods and increased hydroponic farm profitability.

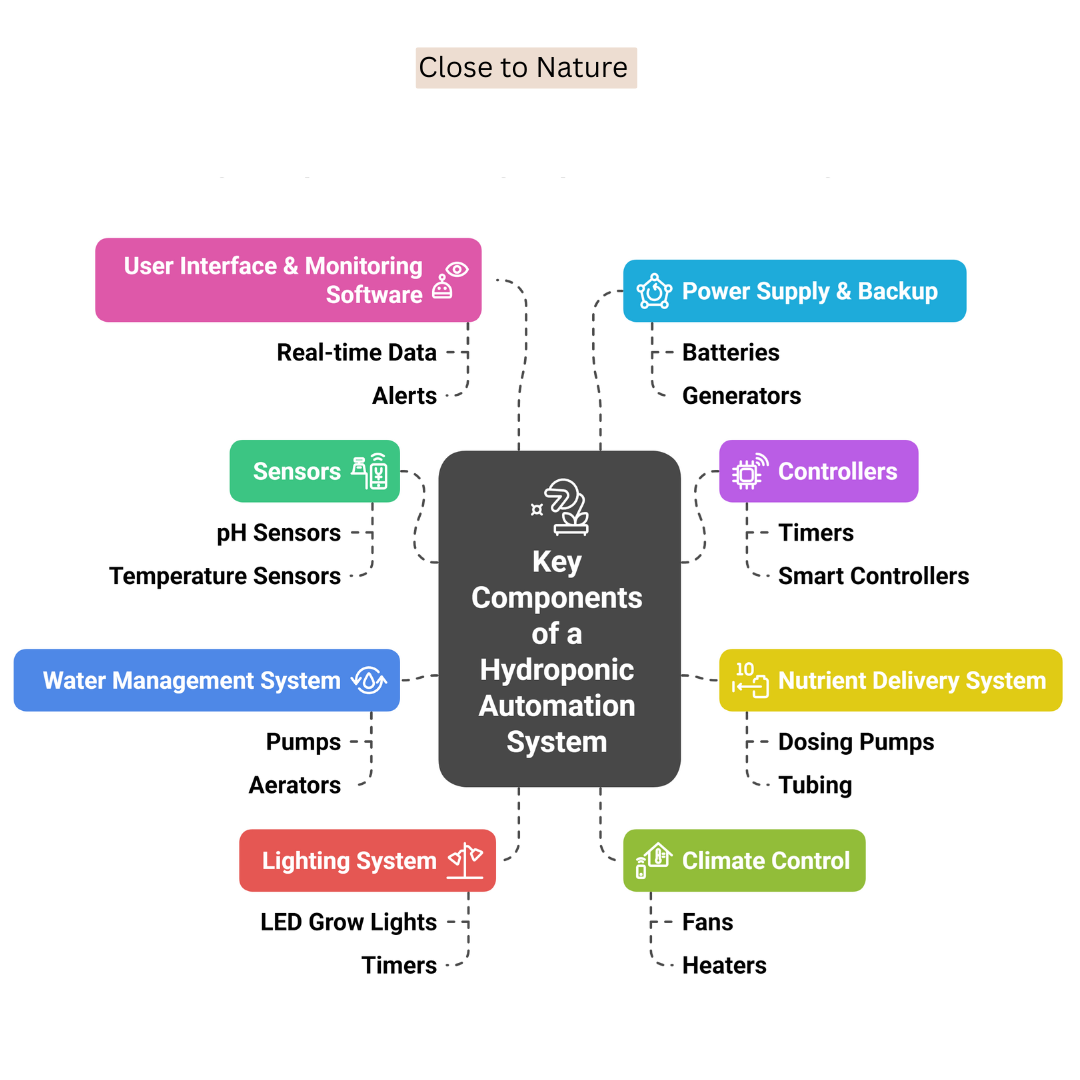

Key Components Of A Hydroponic Automation System

A hydroponic automation system uses advanced components to monitor, control, and optimize plant growth, ensuring consistent yields, reduced labour, and efficient resource use in both home and commercial setups.

1. Sensors

Sensors are the detection tools in a hydroponic automation system, continuously monitoring pH, electrical conductivity (EC), water temperature, air temperature, humidity, and light intensity.

They supply real-time data to the controller so the system can adjust nutrient dosing, climate, and lighting automatically.

Without accurate sensors, the system can’t maintain ideal conditions, which can stunt plant growth or cause disease. Basic pH or temperature sensors cost around $20–$50, while advanced multi-parameter sensors range from $100–$150.

You can buy them from Amazon, Hydrofarm, Growtronix, or agricultural suppliers. Good sensors ensure healthy plants and reduce the risk of crop loss.

2. Controllers

Controllers are the “brains” of a hydroponic automation system. They receive sensor readings and trigger actions such as adjusting nutrient pumps, switching lights, or turning climate devices on and off.

Controllers can be programmed to follow exact schedules or react instantly to environmental changes, keeping conditions stable.

Prices vary from $100 for simple timers to $400 or more for innovative, internet-connected models. You can purchase controllers on Amazon, Hydrofarm, or from brands like Inkbird and Growtronix. A reliable controller is essential for reducing manual work and ensuring your hydroponic system runs efficiently.

3. Nutrient Delivery Systems

The nutrient delivery system feeds plants with a precise mix of water and dissolved minerals. Automated dosing pumps and tubing deliver nutrients directly to the root zone, ensuring the correct concentration at the right time.

This prevents overfeeding, underfeeding, and nutrient imbalances. Prices range from $50 for basic setups to $200 for advanced, sensor-linked models.

You can buy nutrient delivery equipment on Amazon, hydroponic supply shops like Hydrofarm, or specialty farming websites. An efficient nutrient delivery system saves time, conserves resources, and promotes strong plant growth.

4. Water Management Systems

The water management system handles circulation, oxygenation, and storage of nutrient solutions. Pumps and valves keep water moving, preventing stagnation and root diseases.

Aerators ensure oxygen is dissolved for healthy roots, while reservoirs store fresh nutrient solution for delivery. Automated systems can refill and regulate water levels based on sensor data.

Depending on the extent of automation and capacity, prices might vary from $30 to $150. These systems are available on Amazon, in garden centers, and at hydroponic retailers. Plant health depends on effective water management, particularly in closed-loop hydroponic systems.

5. Lighting Systems

A lighting system supplies the correct spectrum and intensity of light for plant growth, especially indoors. LED grow lights are standard for their energy efficiency and adjustable wavelengths.

Automation uses timers or smart dimmers to control light cycles, mimicking natural daylight patterns. This optimizes photosynthesis, boosts growth, and can influence flowering or fruiting.

Quality LED systems cost $100–$300, depending on coverage area and features. You can purchase them from Amazon, Hydrofarm, or specialized grow light suppliers. Reliable lighting is essential for maximum yield in a hydroponic system.

6. Climate Control

Climate control keeps temperature and humidity within ideal ranges for plant growth. It includes fans, heaters, coolers, humidifiers, and dehumidifiers, all triggered by sensor readings.

Proper climate regulation prevents plant stress, mould, and pests. Automation ensures devices operate only when needed, saving energy while protecting crops.

Costs range from $50 for basic fans to $200 for complete climate systems. You can find climate control equipment on Amazon, hardware stores, or hydroponic suppliers. Maintaining the right climate helps plants grow faster and stay healthier in any weather.

7. User Interface & Monitoring Software

User interface and monitoring software allow growers to oversee and adjust their hydroponic system remotely via phone or computer.

It displays real-time data from sensors, logs trends, and sends alerts for potential issues. This technology can be free with basic controllers, while advanced cloud-based systems cost $20–$100 monthly.

Available from hydroponic system manufacturers, Amazon, or software providers like Growtronix, it simplifies management and reduces the need for constant on-site checks. A good interface helps fine-tune growing conditions for better efficiency and yield.

8. Power Supply & Backup

A stable power supply is critical for running pumps, lights, and controllers without interruption. Backup options like batteries or generators prevent crop loss during outages. Automated systems can switch to backup power instantly, avoiding system downtime.

Costs range from $50 for small backups to $300 or more for generators. You can buy them from electronics stores, Amazon, or hydroponic suppliers.

Investing in backup power ensures your hydroponic automation system remains reliable in all situations, protecting your plants and your investment.

Conclusion

By adopting Hydroponic Automation Systems, you can enjoy healthier plants, bigger harvests, and improved efficiency all year round.

This advanced technology handles watering, nutrient delivery, and lighting, allowing you to focus on the joy of growing.

Suitable for both home and commercial use, it ensures consistent and reliable results every season. Upgrade your gardening today and see how automation can genuinely transform your growing journey.

I trust you enjoyed this article on the Best Hydroponic Automation Systems For Faster Growth. Please stay tuned for more blog posts soon. Take care!

JeannetteZ

>>> Please click here to read my all-inclusive article, About The Essential Companion Planting Guide <<<

>>> Please click here to read my all-inclusive article about Container Gardening <<<

>>> Are you interested in homegrown herbs and medicine? Please click here to find out more about it! <<<

Your Opinion Is Important To Me

Do you have thoughts, ideas, or questions? I would love to hear from you. Please leave me your questions, experiences, and remarks about this article on the Best Hydroponic Automation Systems For Faster Growth in the comments section below. You can also email me at Jeannette@Close-To-Nature.org.

Disclosure

This post may contain affiliate links. As an Amazon Associate and other affiliate programs, I earn from qualifying purchases at no extra cost to you. Please read my full affiliate disclosure.

You might also enjoy these blog posts:

Best Types Of Yew Shrubs That Will Transform Your Garden

Feng Shui With Crystals To Transform Your Home

Best Types Of Spirea Shrubs For Easy Gardening

Indoor Vertical Herb Garden Ideas You’ll Love

Ultimate Guide To Feng Shui Numbers For Wealth And Success