Proven Commercial Hydroponic Systems For Maximum Efficiency

Looking to boost your farming efficiency and crop yields? Commercial Hydroponic Systems offer an innovative solution for modern growers.

These systems allow plants to thrive without soil, using nutrient-rich water and controlled environments. Perfect for small and large-scale operations, hydroponics maximizes growth, saves space, and reduces resource waste.

In this blog, we’ll explore the best commercial hydroponic systems, their types, benefits, costs, and step-by-step growing methods.

What Are Commercial Hydroponic Systems?

Commercial hydroponic systems are large-scale setups designed to grow plants without soil, using nutrient-rich water solutions instead.

Unlike small hobby systems, these are fully automated to control light, temperature, humidity, and pH for consistent production.

They are often installed in greenhouses, warehouses, or vertical farms, making them suitable for urban areas with limited land.

These systems maximize space, reduce water usage, and ensure faster plant growth. Popular crops include lettuce, herbs, tomatoes, and strawberries.

With high efficiency and year-round productivity, commercial hydroponic systems are a sustainable and profitable solution for modern agriculture and food businesses.

Types Of Commercial Hydroponic Systems

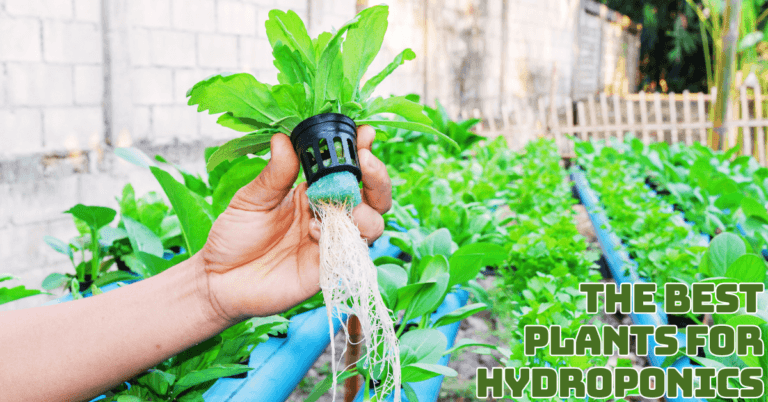

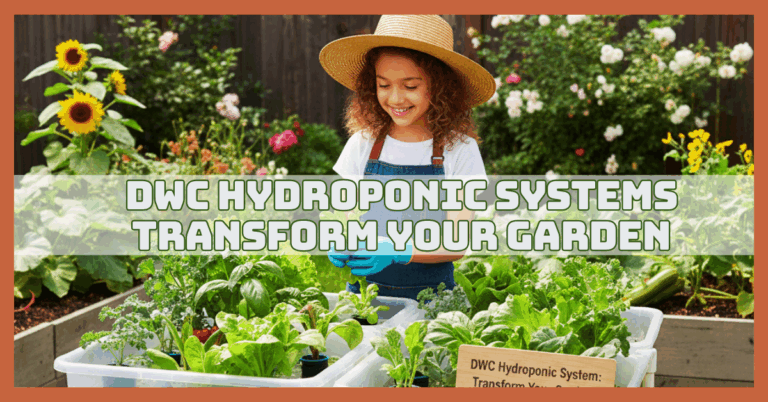

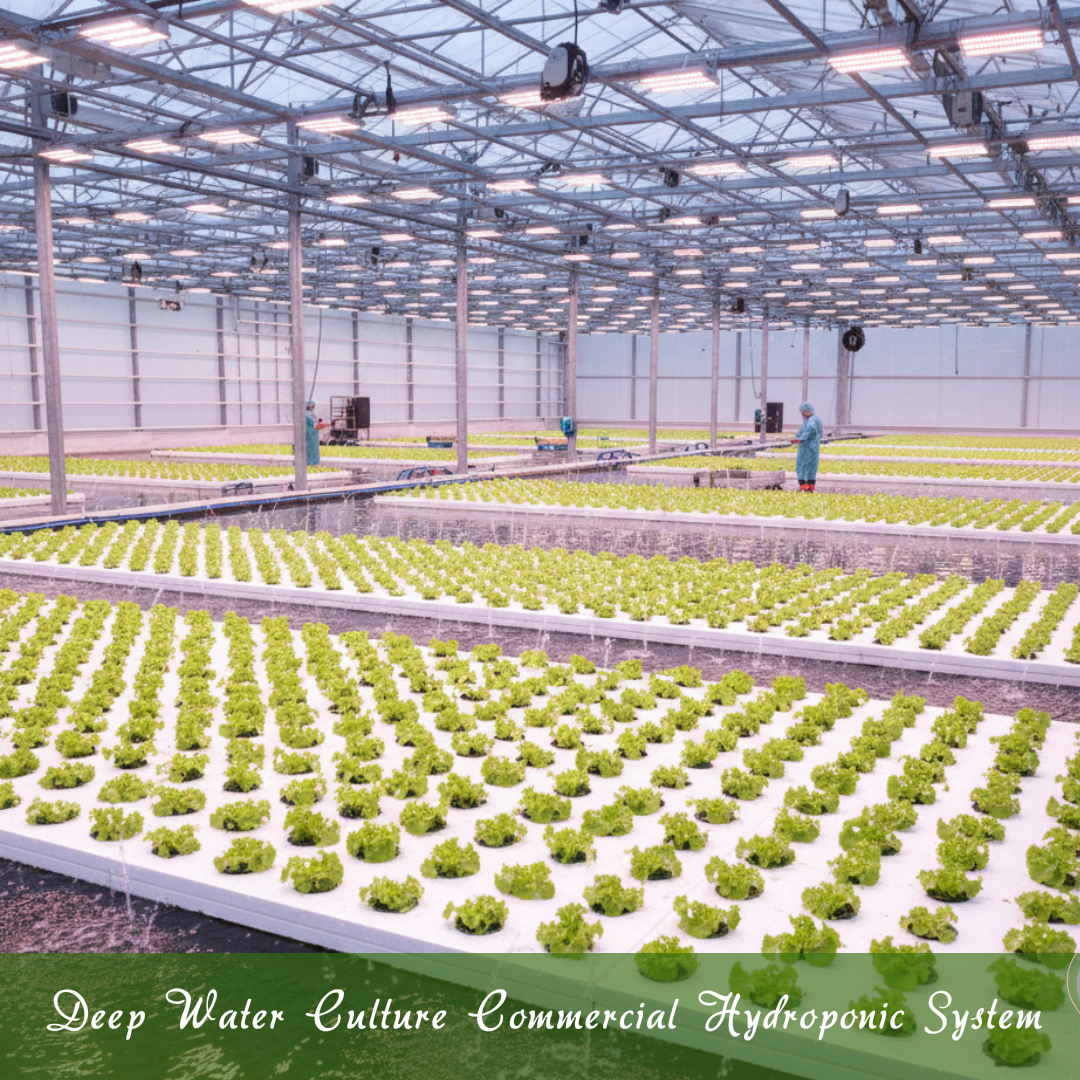

1. Deep Water Culture (DWC) Commercial Hydroponic Systems

Best indoors or in greenhouses. Practically zone-agnostic when climate control is available. Commonly used in temperate regions with greenhouse protection.

Small commercial DWC racks typically range $10,000–$30,000. Medium operations cost $50,000–$150,000. Major expenses include reservoirs, aeration, rafts, plumbing, LED lighting, sensors, and labour. Operating costs include nutrients and electricity for pumps and lights.

Pros

DWC systems are simple to construct and operate, with fewer mechanical parts and straightforward plumbing. They excel for dense leafy crops, give fast growth, and allow easy expansion by adding racks.

Automation is simple, monitoring is direct, labour is reduced, and consistent yields make planning harvest cycles dependable for businesses.

Cons

DWC is less suitable for large fruiting plants due to limited root support and space. It is sensitive to water temperature and oxygen levels; failures can cause rapid crop loss.

Reservoir sanitation is vital to prevent pathogens. Scaling large operations demands redundancy and careful plumbing to avoid systemic failures.

Growing Process

Start with food-safe reservoirs filled with nutrient solution. Attach powerful air pumps with diffusers to oxygenate water. Germinate seeds in rockwool cubes or starter plugs until roots are visible.

Place seedlings into net pots secured in floating rafts, ensuring roots dangle freely into the water. Monitor EC and pH daily, keeping nutrient balance stable.

Water temperature should remain between 65°F and 70°F for healthy growth. Top up reservoirs to replace evaporated water and nutrients.

Change the solution every 2–3 weeks—Sanitize tanks between crops. Harvest leafy greens when mature, then clean rafts and reset the system for the next growing cycle.

2. Ebb and Flow (Flood and Drain) Commercial Hydroponic System

Flexible for greenhouse and indoor setups. Performs well in temperate and subtropical regions. Avoid freezing conditions without proper insulation or climate control.

Typical small commercial ebb and flow benches cost $20,000–$60,000. Larger modular installations with media beds and automation can reach $150,000 or more. Main costs include benches, media, flood tanks, pumps, valves, timers, and periodic media replacement or sanitation.

Pros

Ebb and flow systems are versatile and accommodate both leafy greens and larger fruiting crops in the same facility. Flood cycles oxygenate roots and allow easy maintenance.

Media choices let you tune drainage and water retention. The system is forgiving for mixed crops, allows straightforward retrofits, and supports accessible bench-based workflows.

Cons

Flood timing and drainage must be precise; overflooding encourages root rot while underflooding stresses plants. Media can harbour pathogens if not cleaned or replaced.

Pumps, valves, and timers require reliability and maintenance. Scaling requires careful plumbing design to keep cycles consistent and avoid uneven flooding across benches.

Growing Process

Prepare benches or planting trays with a growing medium, like perlite or clay pebbles. Attach drainage pipes and pumps to trays and a reservoir.

Program timers to flood trays with nutrient solution at scheduled intervals, then drain back into the reservoir. Germinate seeds in starter plugs, then transplant them into the medium when strong roots appear.

Adjust flood frequency based on plant stage and environmental conditions. Monitor EC, pH, and water temperature regularly.

Flush and clean media between cycles to prevent salt buildup. Harvest mature crops, sanitize trays, and reprogram flooding schedules for the next cycle.

3. Drip System Commercial Hydroponic System

Favoured for fruiting crops in greenhouses and controlled indoor environments. Works well in warmer climates and zones where precise fertigation benefits heavy-feeding plants.

Commercial drip installations vary widely. Expect $30,000–$200,000 depending on emitter quality, filtration, fertigation units, and automation.

Costs also include pressure regulators, plumbing, labour for precise layout, and routine filter maintenance to prevent clogs.

Pros

Drip systems deliver nutrients precisely to each plant, ideal for tomatoes, peppers, and cucumbers. They scale well for large plants and support variable feeding schedules.

Water and fertilizer efficiency improve yields. Individual plant control reduces waste, supports targeted pruning and trellising, and helps growers fine-tune fruit quality and harvest timing.

Cons

Emitters require clean water and frequent filtration; clogs are a common maintenance challenge and reduce reliability. The system complexity demands skilled labour for calibration and repair.

Uniform pressure and flow must be maintained. Leaks or misconfigured drippers cause inconsistent growth. Backup plans for pumps and filtration are essential for commercial reliability.

Growing Process

Lay out drip lines and emitters connected to a central reservoir with nutrient solution. Install filtration and pressure regulators to ensure even flow.

Germinate seeds in plugs, then transplant seedlings into containers with a growing medium like coco coir or perlite. Position drip emitters at each plant base and program fertigation schedules based on crop growth stages.

Flush lines weekly to prevent clogging. Adjust nutrient strength and irrigation timing as plants mature, particularly for heavy feeders like tomatoes and peppers.

Regularly replace filters and monitor EC, pH, and flow rates. Harvest crops when ready, sanitize equipment, and restart planting cycles.

4. Aeroponics Commercial Hydroponic System

Best in tightly controlled indoor environments. Not suitable for unprotected outdoor climates. Ideal for operations that can maintain precise temperature, humidity, and high sanitation.

Aeroponic setups are capital-intensive. Small commercial rigs begin near $50,000; high-density installations often exceed $250,000.

Expenses include high-pressure pumps, fine mist nozzles, controllers, filtration, backup systems, and skilled maintenance personnel to ensure reliability and uptime.

Pros

Aeroponics delivers exceptional oxygenation and rapid growth by misting roots with nutrient droplets. Water and nutrient use are highly efficient. Fine root development supports fast cycles and high yields.

The closed, aerated root zone reduces substrate costs. For high-value crops, aeroponics can shorten cycles and boost productivity when reliability is maintained.

Cons

System sensitivity is high; pump, nozzle, or power failures can quickly devastate crops. Nozzle clogging is common and demands rigorous filtration and routine cleaning.

Technical expertise is essential for operation and maintenance. Redundancy, alarms, and backup power are mandatory to protect continuous misting schedules and commercial throughput.

Growing Process

Excellent for leafy greens, herbs, and specialty crops like microgreens. Build sealed root chambers with high-pressure misting nozzles connected to nutrient reservoirs.

Germinate seeds in plugs until roots appear, then suspend seedlings in holders so roots hang freely. Program frequent mist cycles to keep roots moist and oxygenated.

Check droplet size and distribution daily. Maintain sterile water and clean chambers regularly. Use backup pumps and alarms to prevent system failure.

Monitor EC, pH, humidity, and temperature closely. Harvest mature crops carefully, sanitize chambers, and reintroduce seedlings. Aeroponics promotes rapid growth and high yields for delicate, high-value crops.

5. Vertical Farming Commercial Hydroponics Systems

Designed for urban and indoor farms. Essentially zone-agnostic because the local climate is fully regulated. Especially useful where land is limited and logistics favour local production.

Vertical farms carry higher capital expenses for racks, conveyors, multi-tier lighting, and climate control. Small commercial implementations often start near $100,000; large automated farms cost into the millions. Ongoing energy, maintenance, and automation expenses are primary operating considerations.

Pros

Vertical systems multiply output per square foot by stacking layers and using efficient lighting. They support varied crop mixes across tiers and shorten distribution chains. Urban placement reduces transport and waste.

Continuous cycles enable a steady supply to restaurants and retailers. Automation enhances consistency, traceability, labour efficiency, and rapid scale when markets exist.

Cons

Energy demand is significant due to layered lighting and HVAC loads, raising operating costs. Complexity in logistics, access, and harvest increases labour planning.

High upfront investment and technical systems can deter new entrants. Managing microclimates per tier and pest control across layers requires dedicated protocols and careful monitoring.

Growing Process

Ideal for leafy greens, herbs, and compact fruiting crops like cherry tomatoes and strawberries. Plan multi-tier racks and select a hydroponic method per layer, such as DWC or NFT. Install LED grow lights for even coverage.

Connect racks to a central nutrient mixing system with automated pumps—Germinate seeds in plugs and transplant seedlings to assigned tiers. Monitor airflow, humidity, and temperature to maintain consistent conditions.

Schedule staggered planting and harvest for continuous production: clean racks and channels between cycles. Use sensors and automation for nutrient, pH, and EC control. Vertical farming maximizes yields per square foot efficiently.

6. Fogponics Commercial Hydroponic System

Fogponics is best for controlled indoor environments such as greenhouses or vertical farms. It works in temperate to warm zones, where humidity, temperature, and airflow can be carefully managed.

Fogponics systems are high-tech and capital-intensive. Small commercial setups start around $50,000–$70,000. Large installations for high-value crops can exceed $200,000.

Costs include ultrasonic foggers, reservoirs, nutrient mixing systems, sensors, air circulation units, and backup systems. Regular maintenance and specialized expertise add to operational expenses, but water and nutrient efficiency can offset costs over time.

Pros

Fogponics uses ultra-fine nutrient mist to deliver water and nutrients directly to roots. This increases oxygen exposure, accelerates growth, reduces water usage, and allows rapid cycles.

It’s ideal for delicate seedlings, microgreens, and high-value crops. Precision control also minimizes nutrient waste and supports consistent yields.

Cons

Fogponics is extremely sensitive; pump or fogger failure can devastate crops quickly. It requires precise humidity and nutrient management. High upfront costs and technical expertise limit accessibility.

Cleaning and maintaining foggers and filters is labour-intensive. Not ideal for large fruiting plants. System downtime can quickly result in significant losses.

Growing Process

Fogponics is perfect for leafy greens, herbs, microgreens, and delicate seedlings. Start by germinating seeds in starter plugs until roots emerge.

Suspend plants in fog chambers above reservoirs equipped with ultrasonic foggers. The fog delivers a fine nutrient mist to the roots multiple times per hour.

Monitor humidity, nutrient EC, pH, and temperature closely for optimal growth. Ensure chambers are sterile to prevent pathogens. Use alarms and backup systems to protect against failures.

Harvest crops when mature, clean foggers and chambers, and prepare for the next planting cycle. This method maximizes growth efficiency and water savings.

7. Continuous Flow System (CFS) Commercial Hydroponics

Best for controlled indoor environments like greenhouses or vertical farms. Works well in temperate and warm climates where water flow and temperature can be precisely managed.

Small commercial CFS setups cost around $20,000–$50,000, while large-scale systems can exceed $150,000. Main costs include channels or troughs, pumps, reservoirs, sensors, lighting, and automation systems. Regular monitoring and maintenance add to operational expenses but improve crop yield and efficiency.

Pros

CFS continuously circulates nutrient solution past plant roots, ensuring constant nutrient and oxygen delivery. It supports high-density planting, efficient water use, and steady growth.

Automation reduces labour. Works well for fast-growing leafy greens and herbs, providing predictable harvests and consistent quality for commercial buyers.

Cons

Pump or flow failure can quickly damage all crops. Channels must be installed precisely, as slopes affect nutrient delivery. Biofilm and debris buildup are frequent issues.

Systems rely heavily on constant monitoring and backup mechanisms. Limited root space makes it unsuitable for larger fruiting crops, requiring careful crop selection.

Growing Process

CFS is ideal for leafy greens like lettuce, spinach, and herbs. Install channels with a gentle slope connected to a reservoir. Germinate seeds in plugs, then transplant seedlings into net cups so roots contact flowing nutrient solution.

Ensure constant flow and adjust rates to provide steady nutrients and oxygen. Monitor EC, pH, and water temperature daily. Clean channels regularly to prevent biofilm buildup. Use backup pumps and alarms to maintain continuous flow.

Harvest crops according to maturity, then sanitize channels and reservoirs before the next planting. Continuous flow ensures rapid, uniform growth and efficient resource use.

8. Hybrid Commercial Hydroponic Systems

Best for indoor greenhouses, urban vertical farms, or controlled environments. Suitable for multiple climate zones with adjustable temperature, humidity, and lighting controls.

Hybrid systems combine two or more hydroponic methods, costing $50,000–$200,000 for small to medium commercial setups, and $300,000+ for large operations.

Costs include equipment for each method, automation, reservoirs, pumps, lighting, and monitoring systems. Maintenance and staff training are essential.

Pros

Hybrid systems allow growers to customize conditions per crop type. Combines the benefits of NFT, drip, DWC, or aeroponics. Increases flexibility, maximizes yield, and supports diverse crops in one facility.

Efficient for leafy greens, herbs, and fruiting plants simultaneously. Automation simplifies nutrient delivery and monitoring.

Cons

Complexity is higher due to multiple systems operating simultaneously. Higher initial investment and more intensive staff training are required.

Maintenance is more demanding. System failures in one section can affect others. Not ideal for growers seeking a simple, low-tech hydroponic operation.

Growing Process

Hybrid hydroponics works for leafy greens, herbs, and fruiting plants. Select appropriate system types for each crop—DWC for lettuce, drip for tomatoes, NFT for herbs.

Germinate seeds in plugs and transplant according to chosen systems. Monitor EC, pH, water temperature, and humidity for each method.

Program irrigation and nutrient schedules specific to crop needs. Clean and sanitize reservoirs, channels, and emitters regularly. Use alarms and backup pumps to prevent failure.

Harvest crops at maturity, then rotate systems to optimize growth cycles. Hybrid systems maximize space, yield, and flexibility for commercial growers managing multiple crops.

FAQs

1. Which Hydroponic System Is Best For Leafy Greens?

DWC, NFT, aeroponics, and vertical systems are ideal for leafy greens due to rapid growth, high yield, and efficient nutrient delivery.

2. Which Hydroponic System Is Best For Fruiting Crops?

Drip systems, ebb and flow, and hybrid hydroponics are most suitable for tomatoes, peppers, cucumbers, and strawberries because they support heavier plants and precise nutrient management.

Turn Your Passion for Nature Into Income

🌿 Whether you love gardening, caring for animals, or exploring holistic living,

You can share your knowledge online and earn from it.

Discover how nature lovers are growing their passions into meaningful, income-generating blogs. 👇

3. How Long Does It Take To Grow Crops Hydroponically?

Growth is faster than soil farming. Leafy greens can be harvested in 3–5 weeks, herbs in 4–6 weeks, and fruiting crops like tomatoes may take 8–12 weeks, depending on system, light, and nutrient management.

4. What Are The Main Challenges Of Commercial Hydroponics?

Challenges include high startup costs, energy consumption, technical expertise, system vulnerability (pumps, emitters, power outages), disease prevention, and maintaining consistent market access for crops.

5. Can Hydroponics Be Used In Urban Areas?

Absolutely. Indoor or vertical hydroponic systems maximize space and allow urban farms to grow fresh produce efficiently, reducing transport costs and delivering local, pesticide-free crops.

Conclusion

In conclusion, Commercial Hydroponic Systems are transforming modern agriculture, offering higher yields, faster growth, and sustainable farming solutions.

Whether you’re a seasoned grower or just starting, choosing the right system can optimize production and profitability. By understanding the types, costs, pros, cons, and growing methods, you can make informed decisions.

Embrace hydroponics today and take your farming to the next level with these innovative systems.

I trust you enjoyed this article on the Proven Commercial Hydroponic Systems For Maximum Efficiency. Please stay tuned for more inspiring guides, helpful tips, and ideas to help you live closer to nature every day.

Take care!

— JeannetteZ

💬 Your Opinion Is Important To Me

Do you have thoughts, ideas, or questions? I’d love to hear from you. Please leave your comments below or email me directly at Jeannette@Close-To-Nature.org.

📚 More Nature-Inspired Reads

Explore more ways to connect with nature, nurture your pets, and live in harmony with the world around you 🌿